Lew's Model Boats Design Services

Custom 3D Printed Spur Gears & Sets

Your Design Specifications > Lew's Model Boats Design Services > Printed by Shapeways . Shipped to you.

Spur Gears are designed to transmit motion and power between parallel shafts, are the most economical gears in the power transmission industry.

These gears are easy to manufacture, no axial force

relatively, easy to produce high-quality gears.

They are the most common type of gear.

Spur Gears are designed to transmit motion and power between parallel shafts, are the most economical gears in the power transmission industry.

These gears are easy to manufacture, no axial force

relatively, easy to produce high-quality gears.

They are the most common type of gear.

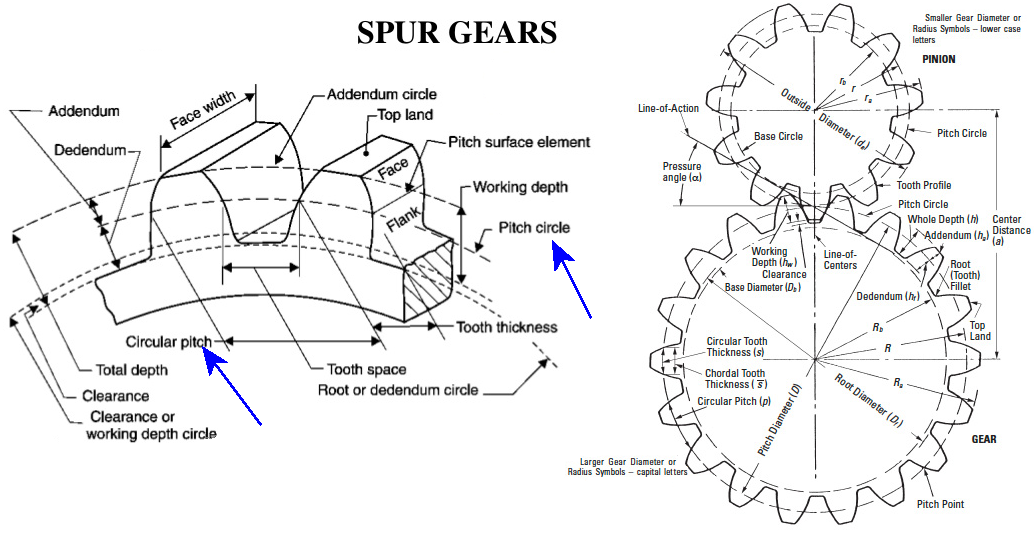

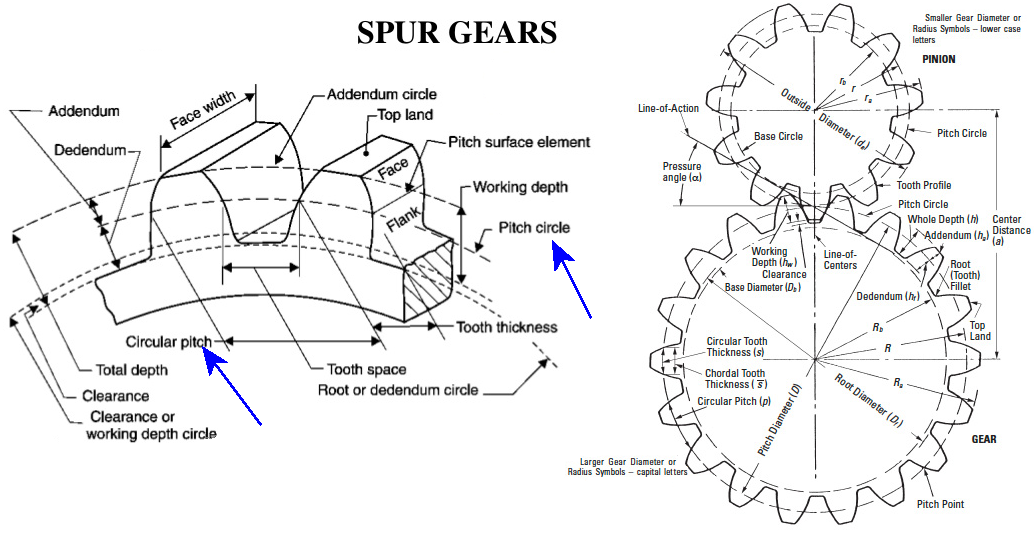

The 20° PA (pressure angle) is recognized as having a higher load carrying capacity and are very common. 14-1/2° PA gears are also extensively used. The difference with the lower pressure angle is reduces change in backlash due to center distance variation and concentricity errors. The 14-1/2° PA also provides a higher contact ratio for smoother, quieter operation.

A simple spur gear is shown at the right. This gear can be customized in various ways, the size, amount of teeth, thickness, a partial gear, holes, shafts attached, and more.

There

are many attributes which define spur gears. The most important features to define are the Pitch Diameter, Pressure Angle, and

Number of teeth. When specifying these numbers the rest are usually determined (calculated) PD, PA, and Number of teeth.

There

are many attributes which define spur gears. The most important features to define are the Pitch Diameter, Pressure Angle, and

Number of teeth. When specifying these numbers the rest are usually determined (calculated) PD, PA, and Number of teeth.

Also needed is the Face Width, which is the thickness of the gear at the teeth.

Once all this is specified, the next step is other features of the gear:

- Is there a hole in the middle, and what size?

- Is there a shaft fixed to the gear, again size plus length?

- Any hubs, size?

- Lightning holes and features?

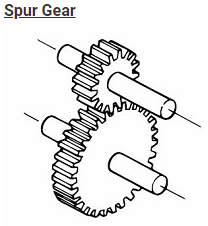

As

you can see in the phot at the right, there are many features to add to the basic gear. The bottom center two

hubs (raised areas) and both have holes, with one of them having a keyway. The two gears in the

center are on shafts. The one in the top left (smaller gear) has a hole for a setscrew in the hub.

As

you can see in the phot at the right, there are many features to add to the basic gear. The bottom center two

hubs (raised areas) and both have holes, with one of them having a keyway. The two gears in the

center are on shafts. The one in the top left (smaller gear) has a hole for a setscrew in the hub.

The gear in the bottom left is actually two gears stacked but all in one piece. This type of gear is also available for design.

Multiple gears (two or more) are available for design. These can be matching sets in order to mate with each other.

The Pressure Angle must be the same for both gears.

Multiple gears (two or more) are available for design. These can be matching sets in order to mate with each other.

The Pressure Angle must be the same for both gears.

The ratio of one ger to the other is determined by the number of teeth and the Pitch Piameter. The Pitch Diameter is the diameter where the gears intersect. (See drawings at the above and right.) One half of the Pitch Diameter of one gear added to one half the Pitch Diameter of the other gear will give the center to center distance of the gear set.

The Diametral Pitch (DP) of a gear is the number of teeth per inch of Pitch Diameter (PD). The Pitch Diameter is also clled the Pitch Circle. It specifies the tooth spacing along the pitch circle of each gear which must be the same for a matching set of gears to work together. This means the gears will mesh. (Refer to the blue arrows in the "Spur Gears" Drawing above.)

Custom 3D Printed Spur Gears & Sets

Your Design Specifications > Lew's Model Boats Design Services > Printed by Shapeways . Shipped to you.

Get the spur gear or gears you want, you specifications, delivered to you.

Lew

About Spur Gears

Spur Gears are designed to transmit motion and power between parallel shafts, are the most economical gears in the power transmission industry.

These gears are easy to manufacture, no axial force

relatively, easy to produce high-quality gears.

They are the most common type of gear.

Spur Gears are designed to transmit motion and power between parallel shafts, are the most economical gears in the power transmission industry.

These gears are easy to manufacture, no axial force

relatively, easy to produce high-quality gears.

They are the most common type of gear.

The 20° PA (pressure angle) is recognized as having a higher load carrying capacity and are very common. 14-1/2° PA gears are also extensively used. The difference with the lower pressure angle is reduces change in backlash due to center distance variation and concentricity errors. The 14-1/2° PA also provides a higher contact ratio for smoother, quieter operation.

A simple spur gear is shown at the right. This gear can be customized in various ways, the size, amount of teeth, thickness, a partial gear, holes, shafts attached, and more.

Getting Spur Gears Made

To get a gear or gears made you need your specifications and possibliity a drawing that has all of the

information sufficient enough to construct a 3D model.

That information is sent via Shapeways' messaging to Lew's Model Boats (link: https://www.shapeways.com/shops/gunboat-61)

In order to get a price quote Lew's Model Boats will need to construct a model and upload it to Shapeways. Shapeways will then determine the cost based on the size (volume needed for the machine, material used, etc. Lew's Model Boats adds a very modest designer fee. Then the producet will be posted with a price and the customer (you) notified.

If you wish to purchase the produst (gear or gears) you then order through Shapeways by selecting the product just like buying any other product on Shapeways.

That information is sent via Shapeways' messaging to Lew's Model Boats (link: https://www.shapeways.com/shops/gunboat-61)

In order to get a price quote Lew's Model Boats will need to construct a model and upload it to Shapeways. Shapeways will then determine the cost based on the size (volume needed for the machine, material used, etc. Lew's Model Boats adds a very modest designer fee. Then the producet will be posted with a price and the customer (you) notified.

If you wish to purchase the produst (gear or gears) you then order through Shapeways by selecting the product just like buying any other product on Shapeways.

Customization

As mentioned earlier, there are many ways to customize a gear.

We will cover all the basics and for anything beyond that a

sketch or drawing will be needed to get you the gear you want.

Parts of the Spur Gear

There

are many attributes which define spur gears. The most important features to define are the Pitch Diameter, Pressure Angle, and

Number of teeth. When specifying these numbers the rest are usually determined (calculated) PD, PA, and Number of teeth.

There

are many attributes which define spur gears. The most important features to define are the Pitch Diameter, Pressure Angle, and

Number of teeth. When specifying these numbers the rest are usually determined (calculated) PD, PA, and Number of teeth.Also needed is the Face Width, which is the thickness of the gear at the teeth.

Once all this is specified, the next step is other features of the gear:

- Is there a hole in the middle, and what size?

- Is there a shaft fixed to the gear, again size plus length?

- Any hubs, size?

- Lightning holes and features?

Other Features of the Gear (holes, shafts, hubs, etc.)

As

you can see in the phot at the right, there are many features to add to the basic gear. The bottom center two

hubs (raised areas) and both have holes, with one of them having a keyway. The two gears in the

center are on shafts. The one in the top left (smaller gear) has a hole for a setscrew in the hub.

As

you can see in the phot at the right, there are many features to add to the basic gear. The bottom center two

hubs (raised areas) and both have holes, with one of them having a keyway. The two gears in the

center are on shafts. The one in the top left (smaller gear) has a hole for a setscrew in the hub.The gear in the bottom left is actually two gears stacked but all in one piece. This type of gear is also available for design.

Material

Various materials are available on Shapeways. The customer will need to specify the material needed.

This will affect the cost. They Shapeways "White Versitile Plastic" is a nylon type material and somewhat

durable. See Shapeways for more information on materials.

Accuracy is based on the Shapeways printing process.

Sets (multiple gears)

Multiple gears (two or more) are available for design. These can be matching sets in order to mate with each other.

The Pressure Angle must be the same for both gears.

Multiple gears (two or more) are available for design. These can be matching sets in order to mate with each other.

The Pressure Angle must be the same for both gears. The ratio of one ger to the other is determined by the number of teeth and the Pitch Piameter. The Pitch Diameter is the diameter where the gears intersect. (See drawings at the above and right.) One half of the Pitch Diameter of one gear added to one half the Pitch Diameter of the other gear will give the center to center distance of the gear set.

The Diametral Pitch (DP) of a gear is the number of teeth per inch of Pitch Diameter (PD). The Pitch Diameter is also clled the Pitch Circle. It specifies the tooth spacing along the pitch circle of each gear which must be the same for a matching set of gears to work together. This means the gears will mesh. (Refer to the blue arrows in the "Spur Gears" Drawing above.)

Ordering Gears

(quotes)

Send a message to Lew's Model Boats through Shapeways' messaging or through my email on the contact page on this site.

Specify the following basic information:

If you want more gears (same or different arrangement) simply supply the information like above but number the gear sequentially.

Example:

Need more help? Contact me.

Specify the following basic information:

Gear #1:

Pitch Diameter: ______________

Diametral Pitch: ______________ (must be the same for matching gears)

Number of teeth: ______________

Pressure angle: ______________ (20 or 14-1/2) (must be the same for matching gears)

Face Width: ______________

Supply additional information such as holes, shafts, hub, or other features for this gear.

Pitch Diameter: ______________

Diametral Pitch: ______________ (must be the same for matching gears)

Number of teeth: ______________

Pressure angle: ______________ (20 or 14-1/2) (must be the same for matching gears)

Face Width: ______________

Supply additional information such as holes, shafts, hub, or other features for this gear.

If you want more gears (same or different arrangement) simply supply the information like above but number the gear sequentially.

Example:

Gear #2:

Pitch Diameter: ______________

Diametral Pitch: ______________ (must be the same for matching gears)

Number of teeth: ______________

Pressure angle: ______________ (20 or 14-1/2) (must be the same for matching gears)

Face Width: ______________

Supply additional information such as holes, shafts, hub, or other features for this gear.

Pitch Diameter: ______________

Diametral Pitch: ______________ (must be the same for matching gears)

Number of teeth: ______________

Pressure angle: ______________ (20 or 14-1/2) (must be the same for matching gears)

Face Width: ______________

Supply additional information such as holes, shafts, hub, or other features for this gear.

Need more help? Contact me.